3' Tuf Rib

Available in 2-3 Days

This is Epic Steel’s most economical metal roofing system. With clean and traditional lines, this panel delivers quality and versatility that is unmatched for the price by any other 40-year roofing material in the industry.

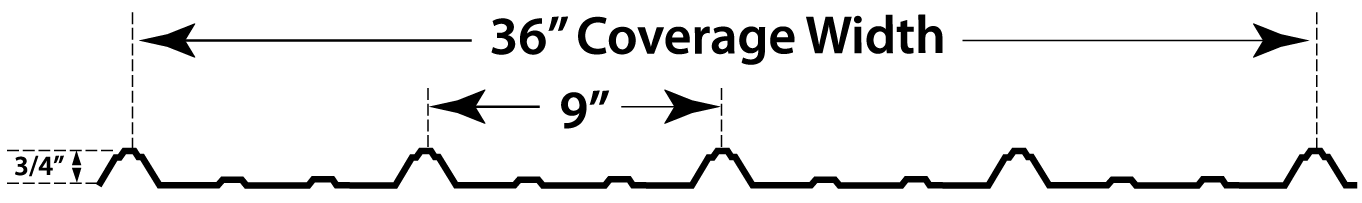

This exposed fastener panel covers 36” after overlap with 9” on center ribs that are ¾” in height. Formed at Epic Steel’s facility, this panel is cut to length and available in just 2-3 days.

Attributes:

Economical, Easy to Install, Fast Turnaround, Versatile, For Use on Open Purlins or Solid Substrate, Manufactured With an Anti-Siphon Groove Overlap System.

- 1 ½” Bearing Length

- Load Span Tables Based on Working Stress

- Flexural Design analysis according to AISI “Specification for the Design of Light Gauge Cold-Formed Steel

- Structural Members” May 1981

- Continuous Span Loading applies to sheets continuous over 3 or more spans

- Weight of sheet has not been allowed for when calculating live loads and uplift.

- Deflection (L/180) limiting live loads based on deflection of span

- Metal thickness based on minimum ASTM specifications for allowable load calculations

- Loads may be increased by ⅓ for wind loads

28

1.98 lb/LF

Stormshield Xt-40, Energystar® Rated, Silicone Modified Polyester

40 Years

Painted and Galvalume

Epic Steel follows the national A.I.S.I. (American Iron and Steel Institute) specifications manual for tolerances in galvanized sheet metal. All gauges conform to ASTM A792 and ASTM A653 Grade E (80,000 min. yield)/ or Grade D (50,000 min. yield) unless otherwise designated at time of order.

Application Details

Slope Requirements

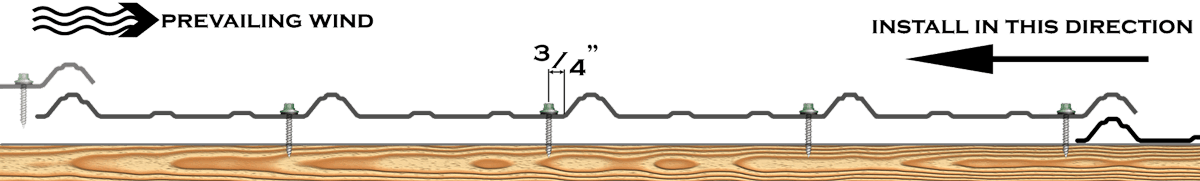

Screw Application

Roof Applications

Technical Specs

Note

Minimum Slope Requirements

|3:12

Screw Application

|#10 Wood grip fasteners are designed for use with dimensional lumber. #14 Wafer fasteners are designed for use with plywood sheeting, OSB and wafer wood (7/16” minimum thickness). #12 Tek screws are designed to be used with structural steel up to 3/16” in thickness.

Roof Applications

|Fasteners to be applied along the side of every rib and attached to each purlin, 2’ on center. Please note that it is the responsibility of the builder to ensure that purlins are adequately spaced to meet specific engineering requirements.

EPIC Steel is neither partially nor solely responsible for improper installation or defects as a result of installation.*Certain colors may be subject to an order minimum and longer lead time. Epic Steel recommends obtaining a color chip prior to placing an order. Please contact your Epic Steel representative to learn more.

Technical Specifications

|- 3′ Tuf-Rib

- Rib Height: ¾”

- Coverage: 36”

- Rib Spacing: 9”

- Gauge: 28

- Most Appropriate Roof Slopes: 3/12 or greater

Note

|The load tables have been compiled for the design of steel roofing and siding used in conjunction with either wood or steel framed structures. EPIC Steel assumes no responsibility, either expressed or implied, for it’s use.

Wind Speeds

70 mph

80 mph

90 mph

100 mph

110 mph

120 mph

130 mph

Live Loads (lbs./sq. ft.)

12.6

16.4

20.8

25.6

31.0

36.9

43.3

Areas of discontinuity are subject to higher spikes in wind pressure, therefore a different coefficient in wind pressure will need to be considered and multiplied by a factor of 1.5.

Technical Specifications

Live Load (Strength)

| SPAN in Feet | 2' | 3' | 4' | 5' |

|---|---|---|---|---|

| 28 Gauge Simple Span | 113 | 45 | 19 | 10 |

| 28 Gauge Continuous Span | 119 | 69 | 36 | 18 |

Uplift Load (Internal Pressure)

| SPAN in Feet | 2' | 3' | 4' | 5' |

|---|---|---|---|---|

| 28 Gauge Simple Span | 113 | 59 | 33 | 21 |

| 28 Gauge Continuous Span | 119 | 74 | 42 | 27 |